Documentation Number Board

Each boat that has Coast Guard documentation (federal) is required to display that unique documentation number somewhere in the interior of the boat. When we bought C Ghost, her documentation number was displayed on the interior of the starboard cockpit locker via a white board with black lettering. If the boat is boarded or inspected […]

Battery Switch Panel Cover

When we replaced all the house batteries and slightly modified the battery compartment on our boat, we decided to install a remote battery switch. The remote switch replaces the familiar big red & black rotary switch found near the battery compartment on almost all boats. It is essentially a very powerful “relay” that can be […]

Snack Tray

Since moving onto on the boat, and spending a lot more time in the main salon, we wanted a convenient place to set down drinks or snacks when sitting on the forward end of the starboard settee. This location is a favorite movie/TV watching position. This is the same area where the dining table folds […]

Breaker Panel Cover

A few years after we got the boat we found we needed to expand the 12V electrical system beyond the original installation that came with the boat. To that end, one of the first things we did was install an additional 12V circuit breaker panel, the subject of one of the very first posts to this […]

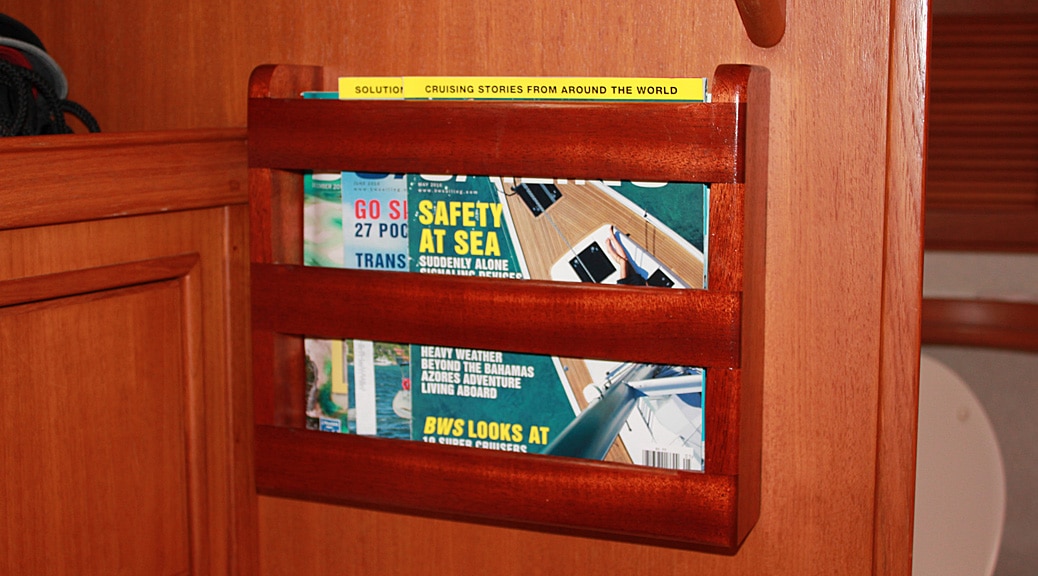

Magazine Rack

We wanted a low profile magazine rack that wouldn’t protrude too much from the wall it was mounted on and also blend in nicely with the teak interior of the IP420.

Spice Rack

There is a perfect place for a spice rack in the IP420 galley under the companion way and against the wall separating the galley from the aft cabin. This custom rack can hold 16 large spice jars and displays three nice nautical themes on the side which faces into the main part of the cabin.

Sea Chest

You know that place at home where you put your wallet and keys and loose change and other small but important stuff? This beautiful sea chest is perfect for that and also makes for a very interesting conversation piece.

Trash Bins

The space around the toilets in each of the heads in our boat does not lend itself to a typical home sized bathroom trash bin. What we needed was a “skinny” enough bin to fit in the small space between the toilet and the wall, but tall enough to overcome the lack of volume from […]

Decorative Plaque

When we bought the boat, there was a hole cut out of the base of the starboard settee that appeared to once house a stereo speaker. We needed something to cover the hole, and asked Paula’s dad to be imaginative. The result is a lovely little plaque with both a compass rose theme as well […]