Since moving onto on the boat, and spending a lot more time in the main salon, we wanted a convenient place to set down drinks or snacks when sitting on the forward end of the starboard settee. This location is a favorite movie/TV watching position. This is the same area where the dining table folds down, and we thought there might be a way to use the bulkhead mounted “box” that supports the dining table to also hold a small snack table. The trick was to make sure it didn’t interfere with the operation of the dining table or when extending out the settee for use as a berth.

We used some cardboard to make a model of a small folding table which would not only meet the above two requirements, but would be nearly invisible when stowed in place. The first set of pictures that follow show our simple mock-up of how the table would work and also how big it would be.

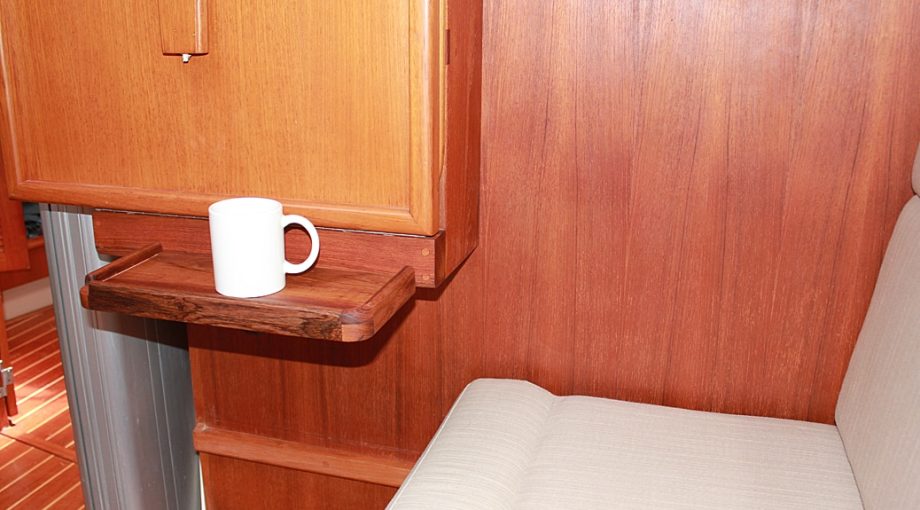

At this point we enlisted Paula’s Dad again to take advantage of his woodworking expertise and cleverness in finalizing the design. We also wanted the tray to have fiddles and a simple way to keep the tray captive in its stowed position. We didn’t mock-up either of these items. He made the tray and support arm from 3/4″ teak stock as well as the fiddles. A clever turnbuckle made from teak to keep the tray in its stowed position rounded out the design. Below are pictures of the unfinished tray mounted to test the fit.

With everything fitting nicely, we unmounted the parts for finishing. Paula was in charge of that and did a very nice rubbed oil finish. I felt a little guilty at this point since it turned out so nice and I hardly did any work!

3 Responses

I am especially proud of the rounded corners made from the same teak. I often wondered how the Tiawanese did it on our woodwork in the Defever, and now I know Ta Da!

Very nice! Our thoughts and prayers are with you as hurricane Irma approaches. Stay safe, Jen

Thanks Jean!