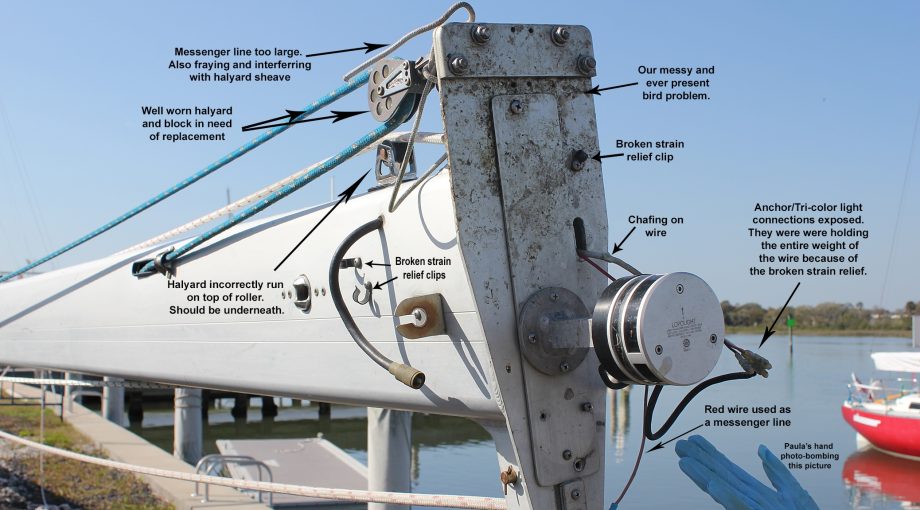

In this article we focus on all the mast work that we were able to do much more easily while it was down on the ground. The featured image above shows the top of the mast once we got our first look at it on the ground. We found a lot of items that needed attention as you can see annotated on the picture.

6 Responses

Here is what popped into my brain when looking at these photos…. that thing has such a little “neck” to support the massive mast. How is that possible??

Good question – the answer is the main reason we are having all this work done. When fully “rigged”, the mast is held up by a lot of support wires in very much the same way a radio tower is supported on land. On a sailboat, those supporting wires are called “stays” and fall into the category of rigging called “standing” rigging. The other category of rigging is called “running” rigging and includes all the ropes used to control the sails. A couple months ago we had all of these wires and ropes inspected by a professional “rigger”. During that inspection, he found cracks in several fittings on the standing rigging as well as some advancing corrosion on a few of the wires. As a result, we decided to have all the standing rigging replaced (all of it was 20 years old). The running rigging was all in good shape.

The pictures in this most recent post do not show any of the standing rigging, only the running rigging. All the standing rigging was removed and shipped out to a company that will make an exact copy of it with new materials. That package of new wires/fittings should arrive early next week and take a couple days to install. Then the mast will be lifted back in place on the boat and all the new wires hanging from the mast will be attached to the boat.

Wow! You guys have sure accomplished a lot in a short time. What does your timetable look like now?

As I mentioned in my reply to K, the package of new standing rigging should arrive early next week. It when it arrives, it will take about three days to assemble and reinstall the mast. We will go back in the water immediately after that. The final tensioning of the new standing rigging must take place in the water since the boat takes on a slightly different shape when floating.

Ah for the life on the bounding main.

It’s because of the “bounding” part of the bounding main that we’re having all this mast work done. Luckily, we’ve been blessed with great weather since the boat’s been out of the water allowing us to make great progress on our part of the work.