During the three weeks our boat was on land, we took care of a number of other boat projects that are more easily done, or only done, with the boat out of the water. That included two things we didn’t even know we’d have to address until we could see the bottom with our own eyes.

Bow Thruster – The first big thing to investigate was an oil leak coming from the axle on our bow thruster. With the propellers off the thruster and all the barnacles cleaned off the drive leg, we could see the oil leaking from an oil seal on the starboard side. We found new oil seals online for 5$ a piece (we decided to replace the one on the port side as well) and paid for expedited shipping. When the new seals arrived, the first chore was to get the old seals out. This turned out to be nearly an all day job.

Rudder Blisters – The next problem to attend to were some fiberglass blisters on our rudder. This is a common problem on many sailboats. The rudder on our boat is the only major structural part not made by the boat builder (Island Packet). In our case, which mirrors that of many others, the rudder manufacturer left a number of small air pockets in the fiberglass layup during construction. Some of these pockets filled with water due to osmotic pressure and began to “bubble”, looking very much like a blister on you skin.

Topsides – The topsides of our hull, the cream color part between the waterline and the deck, is a thin layer of gelcoat over the top of the fiberglass. It is not paint. It tends to oxidize over time and become dull. The easiest time to clean, compound, and wax it is when it is out of the water.

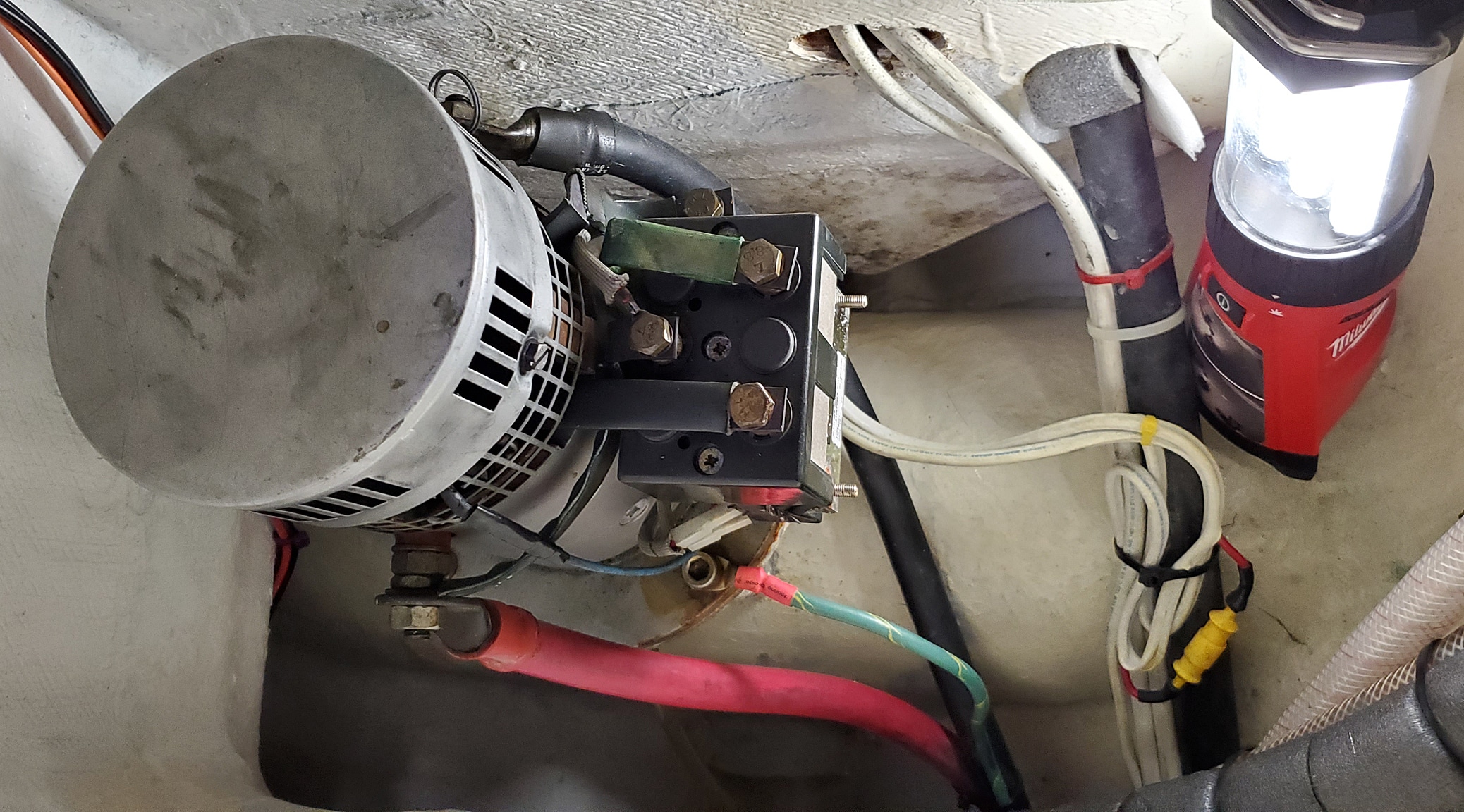

Fridge/Freezer – Our refrigerator and freezer systems work by exchanging the heat they remove with the seawater under the boat. That means they are both inoperative when the boat is out of the water (we had to eat down all our fridge and freezer contents before the haul out). This is the best time to do any maintenance inside the respective boxes since they are thawed out and dry.

Launching – With the mast back up, new rigging in place, bottom painted, and all our other repair work done, it was time to go back in the water.

7 Responses

Very cool, Tom – thanks for sharing!

I follow this guy, who I know. Lots of good boating stories, and also boat tech. https://mvdirona.com/

– Your HS buddy Steve C in Seattle

Thanks Steve! There is plenty more on the site if you want to see some of the things we’ve been up to over the last four years since retiring. And thanks for the link. I’m always interested in the boating adventures of others, and love the tech stuff. A big part of the fun of this lifestyle for me is the never ending set of interesting engineering challenges. The learning never stops.

Almost forgot – your email address is awesome.

Awesome… but have to tell you that at first, all I saw was Paula going head first into the freezer and the words “bow thruster”.

An instant attention grabber ??

Thank you both for your always great comments. We love them. Now that we are back in our home slip, there is a lot of “re-assembly” to be done on the boat from things we had to remove before the haul-out. As you may have noticed in all the pictures, most of our canvas was down so it wouldn’t be in the way of the riggers. We re-installed all that yesterday. Of course, all three sails were removed from their furler’s (along with the furling lines) and we will be attempting to put them back on today. We also just re-started both the fridge and freezer and now have to re-stock on food. Everything should be back to normal in another few days.

There’s an old saying, “You could write a book about it”. This certainly applies to the renewal of C-Ghost. Love, Dad

WOW! I just can not get over the fact that both of you were able to take on so many side jobs, unexpectedly identified, along with the ones you already had in mind. Congratulations to both of you along with hugs! Mom C.